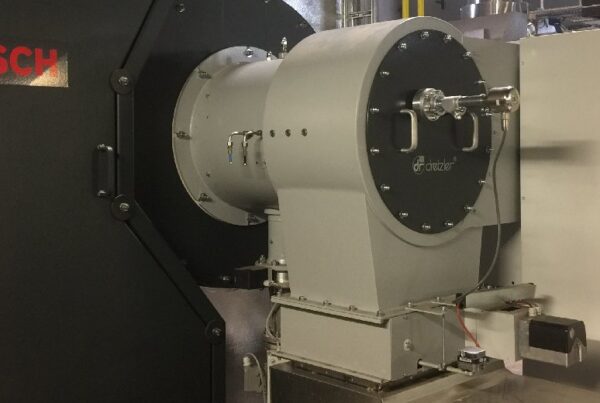

dreizler®

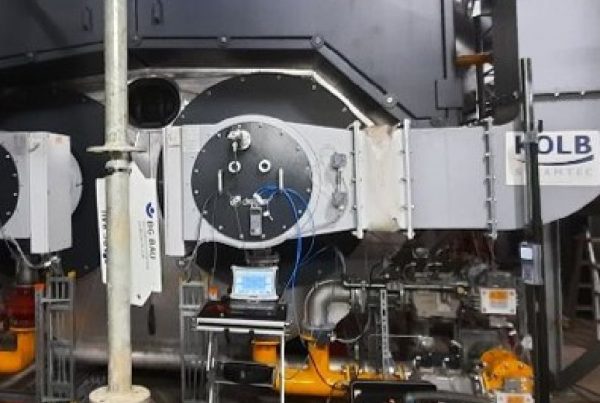

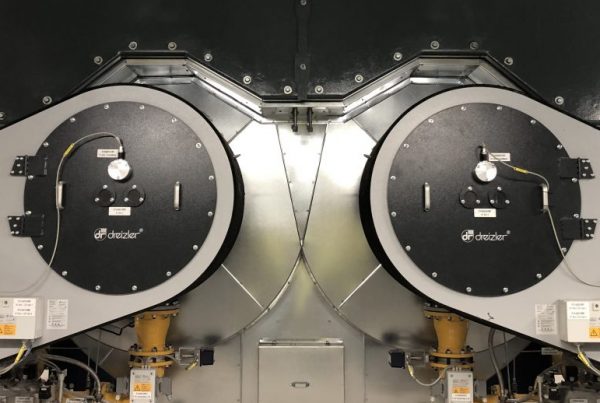

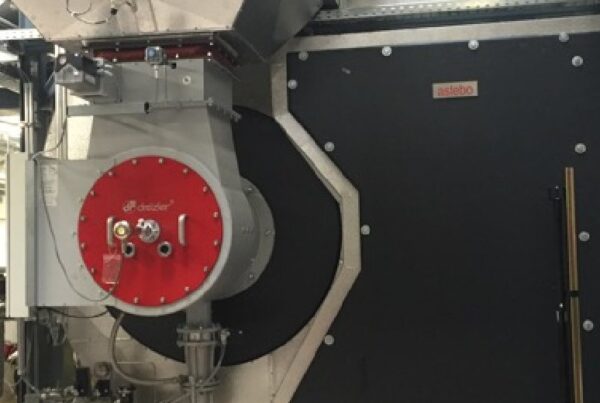

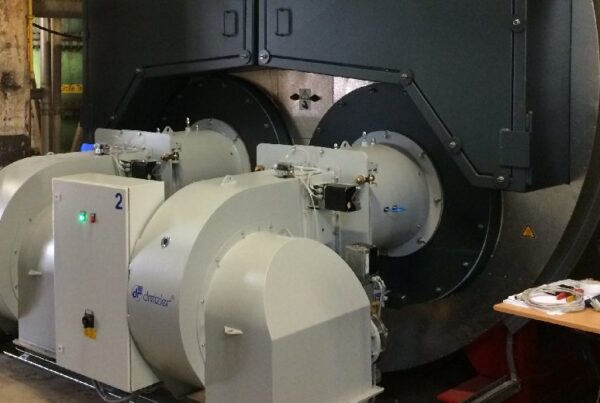

Installation Examples

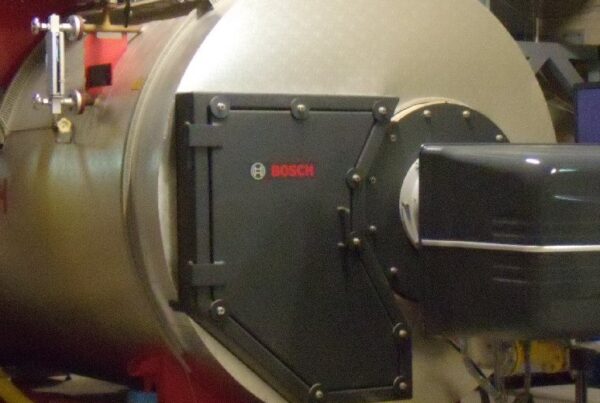

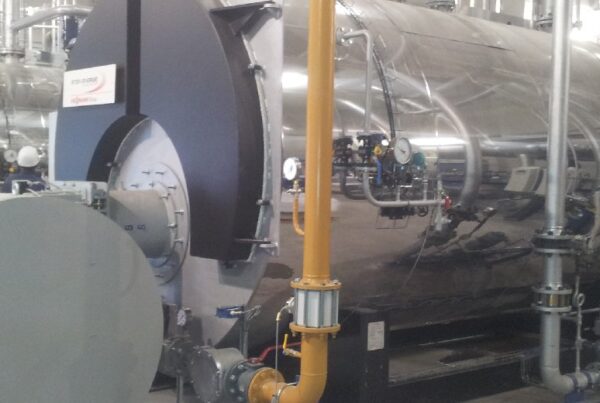

Renowned customers consider us an innovative partner for burner technology. Each year, Each year, we supply up-to-date, efficient combustion systems with an overall firing capacity of more than 2 gigawatts for heating and process heat as well as steam generation.

When it comes to experience, expertise and absolute reliability: heating systems with marathon® burners made by dreizler® are something to be proud of.

- All

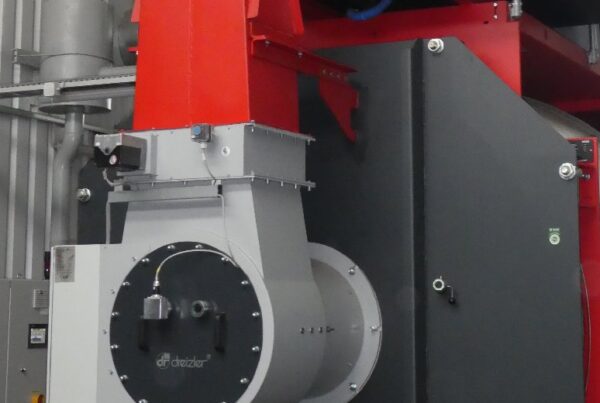

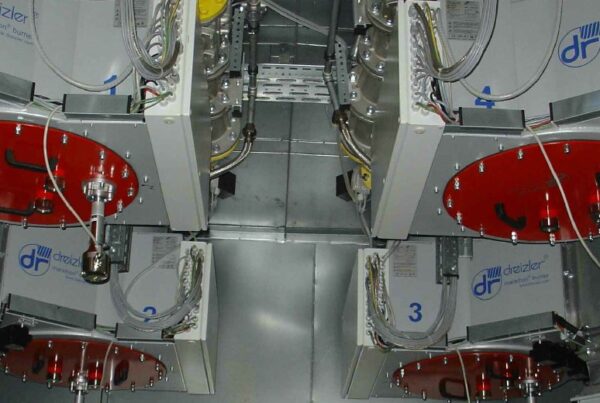

- Duobloc burners

- Installations Dairy Industry

- Monobloc 5000er

- Installations Water Tube Boilers

- Installations Heating Plants

- Installations Cogeneration Plants

- Installations Paper Industry

- Installations Thermal Oil

- Best Practice

- Installations

- Installations Breweries

- Monobloc burners

- Monobloc all sizes

- Installations Food Industry

- Installations Process Heat