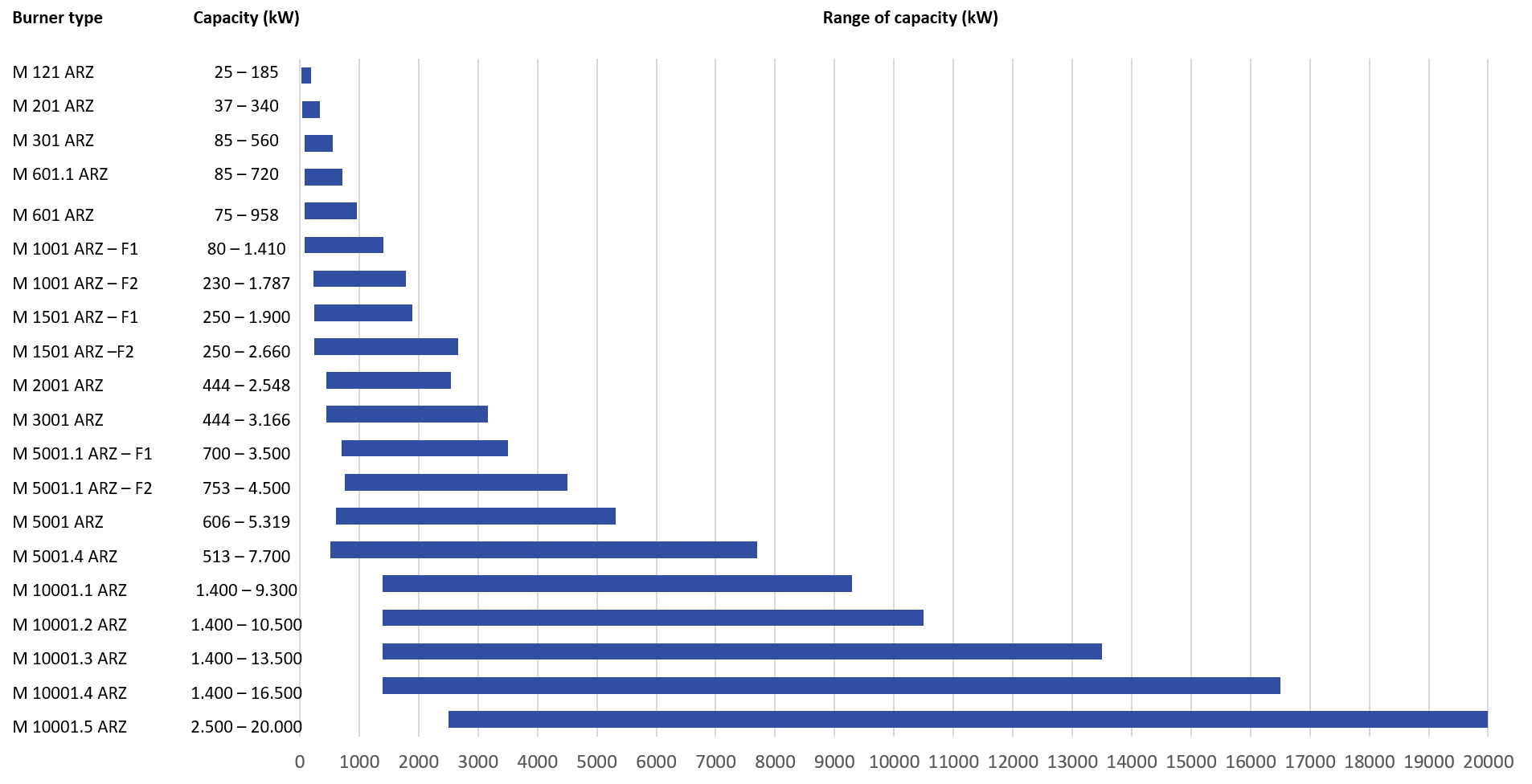

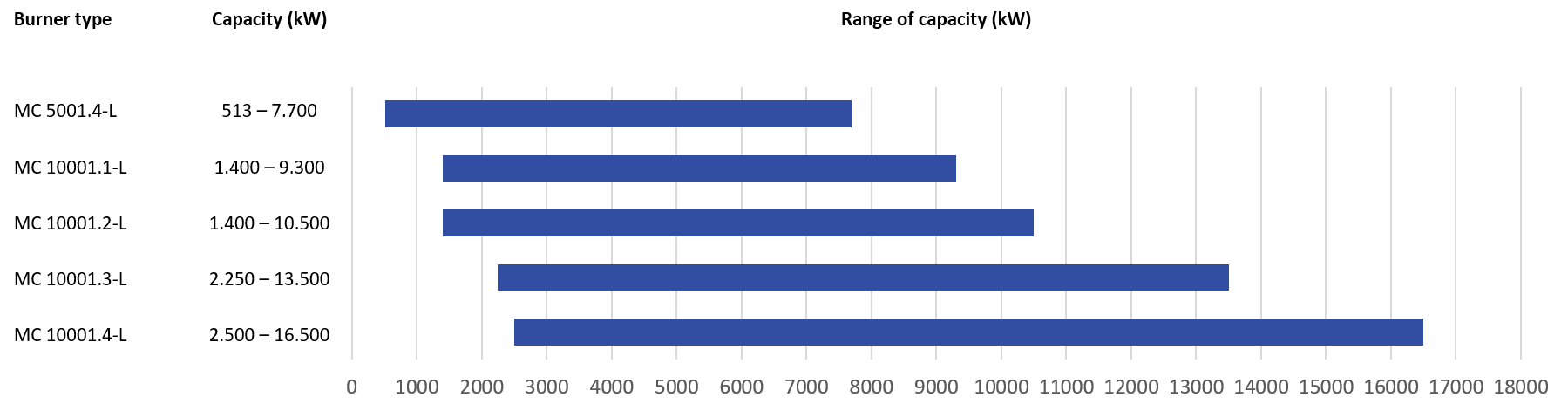

MONObloc up to 20 MW

Compactly designed powerpack with built-in combustion air fan

- Integrated burner control system

- Compact and maintenance-friendly design

- Electronic linkage

- Available as gas burner, dual fuel burner or oil burner

- Retrofitting an existing oil burner to dual fuel burner at any time

- Each dual fuel burner can be operated purely with oil

Up to 80% electricity savings

with dreizler® frequency

Reduction of NOx emissions

with dreizler® ARZ/ARZsuper

Combustion optimization

with dreizler® oxygen/oxygenplus

Features

- Modulating burner regulation

- Elektronic linkage

- Simultaneous combustion of at least two fuels in gaseous or liquid form possible

- Control ratio for gas up to 1:10

- Control ratio for oil up to 1:4

- Gas trains according to EN 676

- Oil mountings according to EN 267

- Noise dam cap serial and optional

Fuels

Certification

- natural gas

- hydrogen

- liquid gas (LPG)

- city gas

- biogas

- special gases

- fuel oil EL (others on request)

marathon® gas burners are certified in accordance with EN 676 Forced draught burners for gaseous fuels as well as EC-type tested.

- CE-0085AP0743 / CE-0085AQ0360

marathon® dual fuel burners are certified in accordance with EN 676 Forced draught burners for gaseous fuels and EN 267 as well as EC-type tested.

- CE-0085AT0266

Optional hightech equipment

- Delivery of the burner in DUObloc version for additional charge

- Parameter driven PID load ratio control with temperature or pressure sensor

- Patented flue gas recirculation ARZ/ARZsuper for extra low NOx-emissions

- Speed control frequency with saving of current consumption up to 80 %

- Residual oxygen control oxygen for combustion optimising

- Residual oxygen control oxygenplus with CO limit value control for additional fuel utilisation

- Equipment according to Pressure Equipment Directive 2014/68/EU for fired pressure equipment (e.g. steam boiler)

webCOBRA®

burner configurator

Use our free online tool to configure your dreizler® burner according your requirements and wishes!

Contact

Do you have questions or need a quote?

We will be happy to provide you with more information.