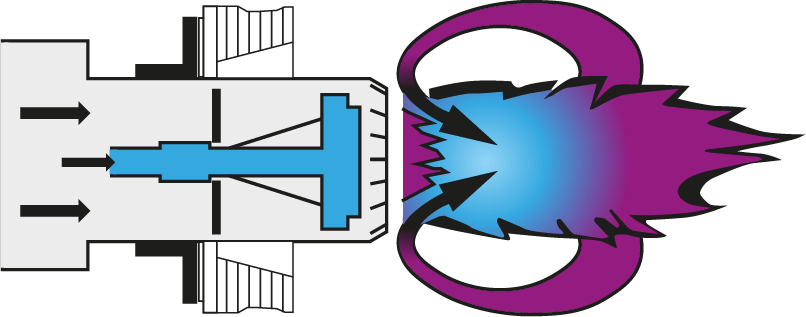

Flue gas recirculation ARZ integrated in gas burner’s head for particularly low NOx emissions.

dreizler® ARZ and ARZsuper

Exemplary emission values

Flame technology for reduction of NOx emmissions

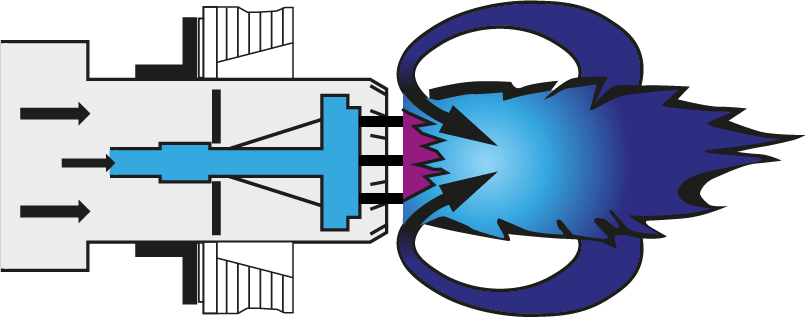

Flue gas recirculation ARZsuper for clean combustion in dual fuel burners.

System description

Flue gas recirculation implies the recirculation of completely combusted flue gases with a lower oxygen and comparatively high CO2 content into the combustion process. Even small amounts of inert flue gases in the combustion result in a reduction of thermal NOx formation.

Internal flue gas recirculation uses pressure differences in the mixing unit and the combustion chamber to return flue gas directly from the combustion chamber back to the burner mixing unit and into the flame.

The patented flue gas recirculation ARZ or ARZsuper excellently reduces NOx emissions in dreizler gas and dual fuel burners to exemplary emission values.

Your benefits

- Optimal fuel optimization with lowest possible emissions

- applicable for gaseous as well as liquid fuels

Contact

Would you like to learn more about emissions reduction through flue gas recirculation?

Request our info sheet here.