System Description

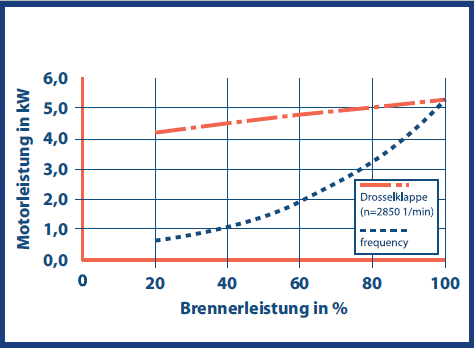

Due to the continuously variable speed control supplied by a frequency converter on the motor, the combustion air fan delivers exactly the amount of air required for the burner’s respective load point.

The dreizler® frequency technology allows you to realize power consumption savings of up to over 75%, enabling an incredibly quiet burner operation at the the same time.